The compositions of regular indole or moulded insole are fleece or terry toweling laminating EVA foam with solvent-based adhesive and cutting in the form of insole or through hot compress and fixation to become moulded insole. The shortcoming of this process is the residues of toluene or VOC. So we use hot melt adhesive film instead of solvent-based adhesive to eliminate the residues of VOC and shorten the process.

- Regular insole:

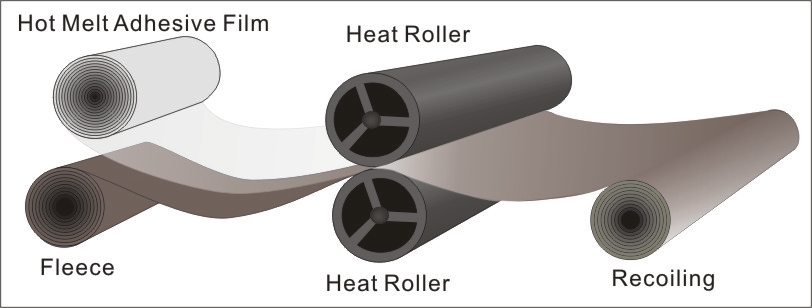

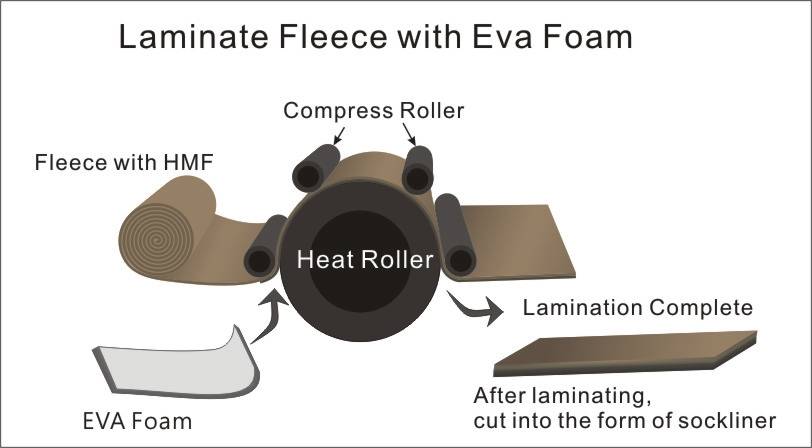

a. Laminate hot melt adhesive film on the fleece or directly coating hot melt adhesive film on the fleece.

b. Use general hot press laminator. Hot press fleece and EVA foam.

c. After laminating, cut into the form of the regular insole.

2. Moulded insole:(Hot compress and fixation)

- Cold model:

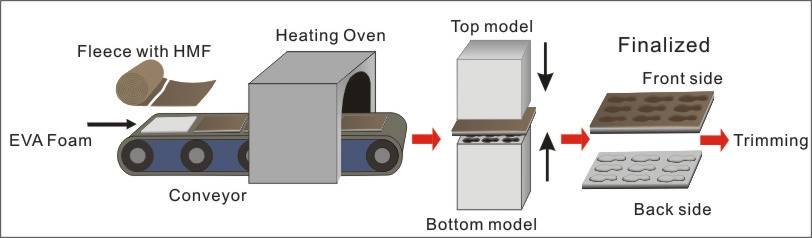

- Laminate hot melt adhesive film on the fleece or directly coating hot melt adhesive film on the fleece.

- Fleece and EVA foam passing through the heating oven at the same time. When the two come out of the oven, directly send into the cold model to compress and fixation.

- After finalized, trim the excess material.

II. Hot model:

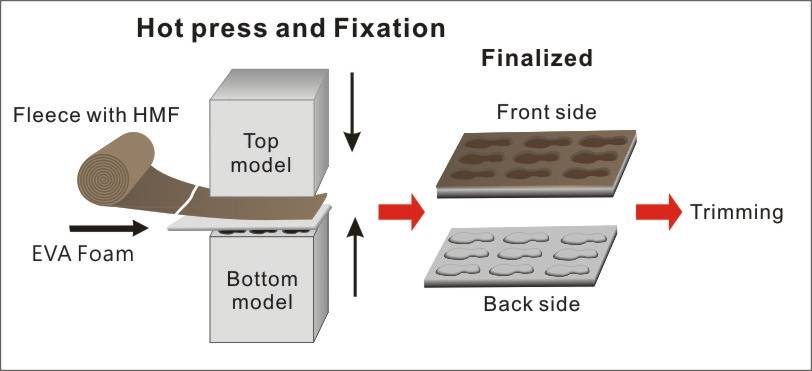

a. Laminate hot melt adhesive film on the fleece or directly coating hot melt adhesive film on the fleece.

b. Lay the fleece on EVA foam and then compress in the hot model then cooling down to fixation.

c. After finalized, trim the excess material.

OPERATING CONDITION:

|

1 |

Operation method |

heat-molding by roller |

|

2 |

Temperature, Roller S.T. |

100~130 oC _4.9 kgf/cm2 (depend on the material) |

|

3 |

Roller time |

20 sec(above) (depend on the material) |

EH-935F is a film without solvents designed to assembling sockliner materials such as textiles v.s EVA foam.

PHYSICAL PROPERTY:

|

1 |

Appearance |

Translucent film(without releasing paper) |

|

2 |

Thickness |

0.04 mm*n,n=1,2,3….ex:0.04mm,0.08mm,0.12mm… |

|

3 |

Flowing temperature |

85±5 oC |

|

4 |

MI (2.16 kg,190oC) |

22±5g/10min |

|

5 |

Specific Gravity |

0.9 g/cm3 |

|

6 |

Hardness |

88±3A |

|

7 |

Solvent |

No |

|

8 |

Shelf life |

one year |

|

9 |

Packing:

|

Width below 150cm/ ROLL Length depends on thickness: 1. 0.04 and 0.08 mm thickness: 400 M (length) / ROLL 2. 0.12 mm thickness: 250 M (length) / ROLL 3. 0.16 mm : 200 M (length) / ROLL 4. 0.20 mm : 150 M (length) / ROLL |