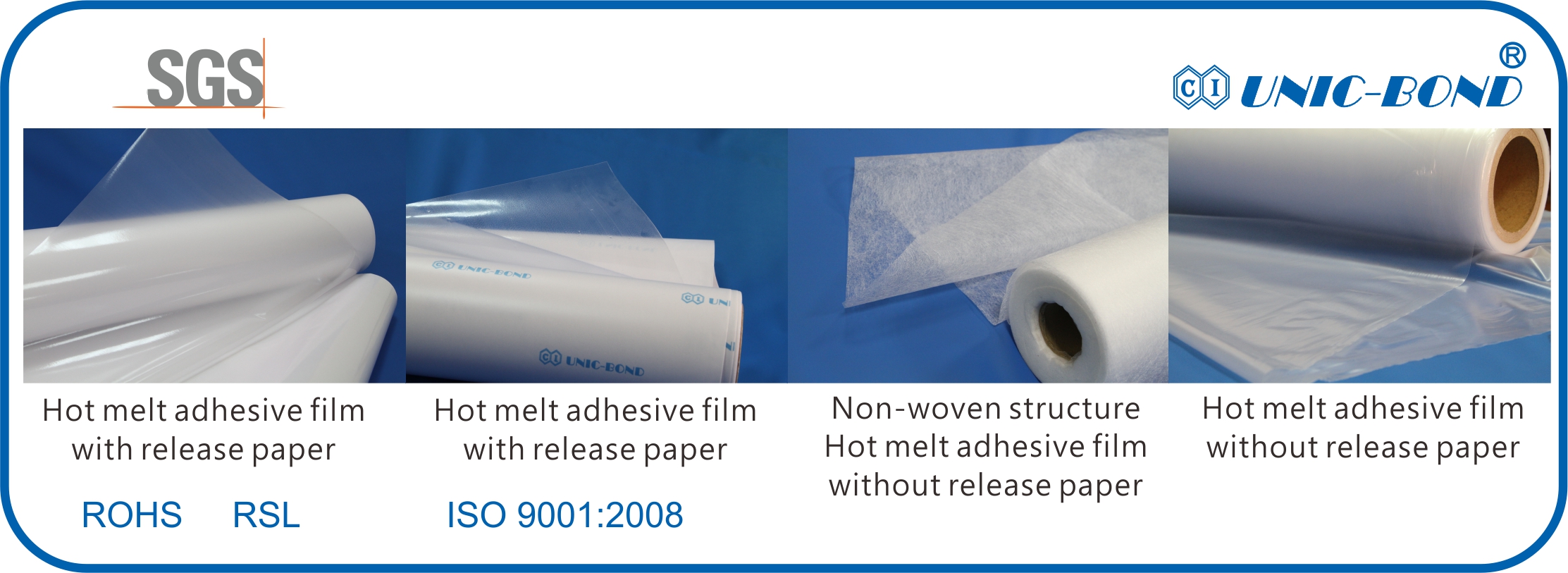

CH Series: PU film, suitable for cloth, soft and hard PVC, wood, TPU skin.

EH Series: Polyolefin film, suitable for rubber, EVA foam, cloth, metal.

PH series: Polyester, polyamide film, suitable for cloth, synthetic leather, metal.

Adjusting by the condition is necessary.

|

Item |

Hardness |

Appearance |

(RDA-II)Fluid Temperature |

100% Modulus |

Tensile Strength |

Recommended |

Specialized Properties |

|

CH-815 |

90±3A |

Translucent |

100℃±5℃ |

49±5 |

230 |

120℃_9.8kgf/cm2_20sec |

Moderate Hardness, It can be used for safety wear, Hook and loop straps |

|

CH-817 |

73±3A |

Transparent |

90℃±5℃ |

27±5 |

100 |

120℃_9.8kgf/cm2_20sec |

soft, good heat resistance, Operating at Low Temperature, textile bonding |

|

CH-822 |

62±3A |

Transparent |

110℃±5℃ |

17±5 |

270 |

130℃_9.8kgf/cm2_20sec |

soft, good elastic and heat resistance, flexible material(eg.Lycra) bonding |

|

CH-824 |

78±3A |

Transparent |

110℃±5℃ |

27±5 |

350 |

130℃_9.8kgf/cm2_20sec |

Soft, Good Elastic Response, Operating at Low Temperature, for shoe-making |

|

CH-826 |

76±3A |

Transparent |

105℃±5℃ |

38±5 |

300 |

140℃_9.8kgf/cm2_20sec |

Soft, Good Elastic Response, Heat Resistant, Mobil phone shell |

|

CH-826A |

80±3A |

Transparent |

118℃±5℃ |

29±5 |

210 |

150℃_9.8kgf/cm2_20sec |

Soft, Good Elastic Response, Heat Resistant, Mobil phone shell |

|

CH-829 |

82±3A |

Transparent |

98℃±5℃ |

45±5 |

350 |

130℃_9.8kgf/cm2_20sec |

good heat resistance and good resistance to yellowing, good anti-hydrolysis, Shoe-making , carbon fiber bonding |

|

CH-910 |

95±3A |

Translucent |

60℃±7℃ |

90±5 |

300 |

130℃_9.8kgf/cm2_20sec |

Hard, for bonding PC, ABS, Mobil phone case |

|

CH-922 |

80±3A |

Non-woven |

110℃±5℃ |

- |

- |

130℃_9.8kgf/cm2_15sec |

It can be use on Cloth, breathable. Interlining bonding |

|

CH-927A |

80±3A |

Translucent |

105℃±5℃ |

50±5 |

230 |

130℃_9.8kgf/cm2_30sec |

good heat resistance, Operating at Low Temperature , textile, Vamp ,without release paper |

|

CH-966 |

53±3D |

Translucent |

55℃±5℃ |

85±5 |

220 |

80℃_9.8kgf/cm2_20sec |

Hard, Operating at Low Temperature |

|

EH-342 |

85±3A |

Transparent |

80℃±5℃ |

69±5 |

150 |

110℃_9.8kgf/cm2_10sec |

Operating at Low Temperature ,Good Bonding to metals |

|

EH-343 |

80±3A |

Transparent |

90℃±5℃ |

67±5 |

200 |

140℃_9.8kgf/cm2_30sec |

Good Bonding to metals |

|

EH-346 |

88±3A |

Transparent |

115℃±5℃ |

62±5 |

185 |

150℃_9.8kgf/cm2_30sec |

Good Bonding to Metalsl |

|

EH-931 |

90±3A |

Translucent |

117℃±5℃ |

45±5 |

150 |

180℃_9.8kgf/cm2_30sec |

good heat resistance, Good Bonding to metals, PE, without release paper |

|

EH-932 |

92±3A |

Transparent |

130±5℃ |

77±5 |

250 |

150℃_9.8kgf/cm2_30sec |

good heat resistance, Good Bonding to metals, PP, without release paper |

|

EH-933B |

81±3A |

Transparent |

100℃±5℃ |

45±5 |

300 |

130℃_9.8kgf/cm2_30sec |

It can be use on Cloth, Shoe Material ,( RB vs EVA inmold lamination ) |

|

EH-935F |

88±3A |

Translucent |

85℃±5℃ |

43±5 |

70 |

105℃_9.8kgf/cm2_30sec |

Sockliner ( EVA foam bond with Textile ) ,without release paper |

|

EH-936 |

84±3A |

Transparent |

112℃±5℃ |

45±5 |

160 |

150℃_9.8kgf/cm2_15sec |

It can be use on Cloth, Shoe Material, Sockliner |

|

EH-937 |

92±3A |

Transparent |

110℃±5℃ |

120±5 |

180 |

140℃_9.8kgf/cm2_30sec |

good heat resistance, Good Bonding to metals, PE, without release paper |

|

EH-943 |

90±3A |

Transparent |

105℃±5℃ |

63±3 |

300 |

140℃_9.8kgf/cm2_30sec |

good heat resistance, Good Bonding to metals, PE, without release paper |

|

PH-924 |

57±3D |

Non-woven |

115℃±5℃ |

- |

- |

130℃_9.8kgf/cm2_20sec |

Breathable, It can be use on Cloth, interlining bonding, Dry-Clean |

|

PH-942 |

95±3A |

Translucent |

110℃±5℃ |

110±5 |

370 |

140℃_9.8kgf/cm2_20sec |

It can be use on Cloth, Logo, Hook and loop straps , Washable≦60℃, Dry-Clean |

|

CH-426 |

78±3D |

Translucent |

100±5℃ |

- |

150 |

150℃_9.8kgf/cm2_20sec |

good heat resistance, Good Bonding to metals, PET |

|

RF-115 |

- |

Brown film |

- |

- |

- |

pre-lamination: 120℃_9.8kgf/cm2_5sec Bonding: 180℃_9.8kgf/cm2_10min |

It is a reactive mounting type, can be use on glass, Aluminum and other alloy, carbon fiber sheet |