FEATURES

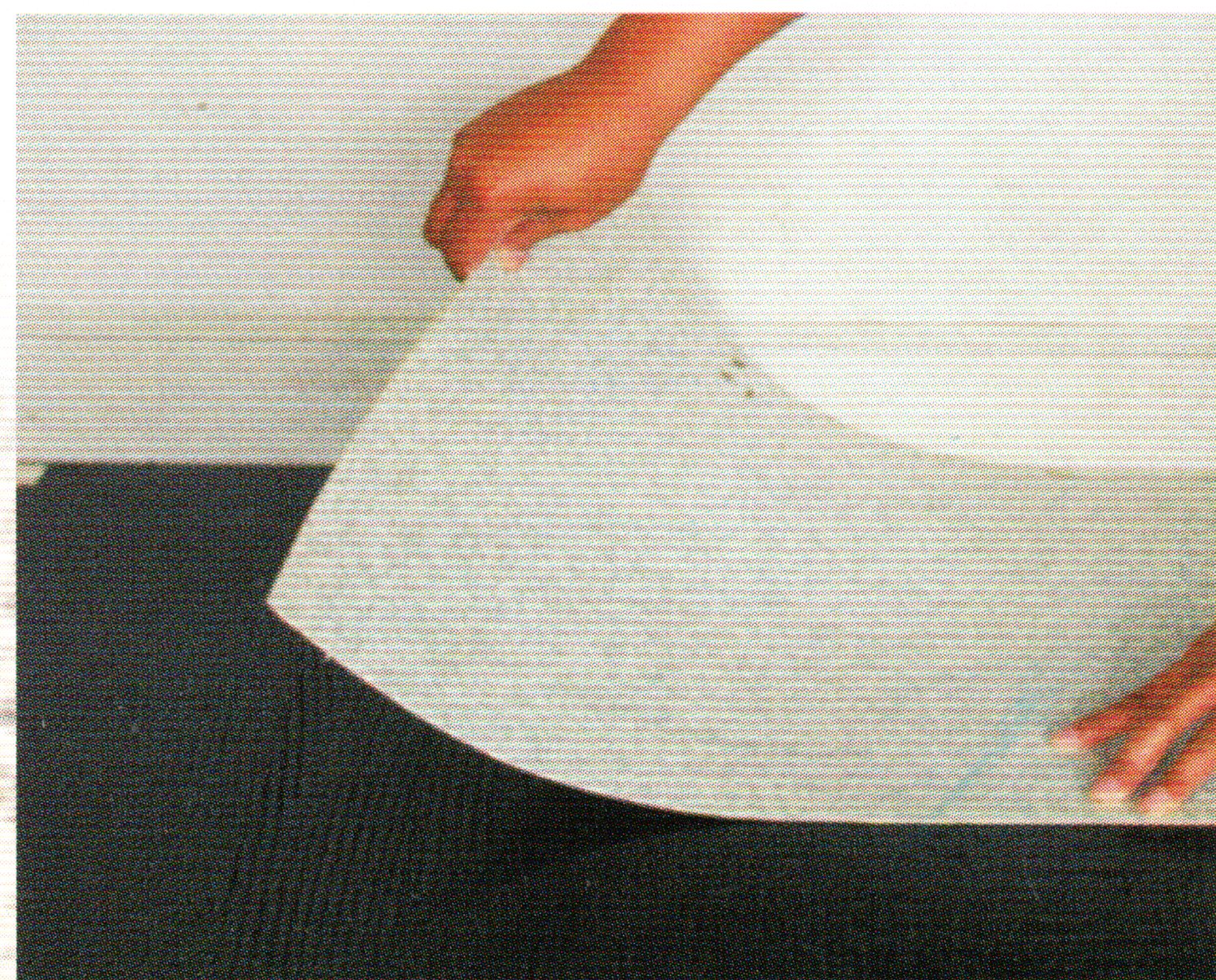

PREPARATION:

Operating procedure

CLEANUP

STORAGE LIFE

COVERAGE

Double Fish Conductive PVC Flooring Adhesive 3010 Test Data

Test Equipment: D esco 19770 Surface impedance meter

Testing Standards: ESD S7.1 Test Method

Trowel Specifications: Tooth width 2mm, Tooth deep 1.55mm, Pitch 8mm

Temperature: 29.9 °C

Humidity: Drill to 17 degrees, Air Humidity 74%

Test 1 Cement + Conductive Floor Tiles

|

|

Test Date |

Test Time |

Temperature in °C |

Humidity Test |

Ground Testing |

Surface Test |

|

Adhesion Time |

2001.9.5 |

10:00 |

33 |

67% |

4.6*10⁴ |

1.1*10⁵ |

|

24 hours |

2001.9.6 |

07:50 |

28.8 |

68% |

5.2*10⁴ |

9.6*10⁴ |

|

48 hours |

2001.9.7 |

07:50 |

28.1 |

68% |

4.3*10⁴ |

9.0*10⁴ |

|

72hours |

2001.9.8 |

08:30 |

28.9 |

69% |

5.4*10⁴ |

1.6*10⁵ |

|

9 days |

2001.9.14 |

08:30 |

29.4 |

65% |

3.3*10⁴ |

1.0*10⁵ |

|

14 days |

2001.9.19 |

07:40 |

28 |

77% |

7.3*10⁴ |

1.6*10⁵ |

Test 2 Cement + Conductive PVC Carpet Tiles

|

|

Test Date |

Test Time |

Temperature in °C |

Humidity Test |

Ground Testing |

Surface Test |

|

Adhesion Time |

2001.9.5 |

10:00 |

33 |

67% |

1.7*10⁵ |

3.5*10⁵ |

|

24 hours |

2001.9.6 |

07:50 |

28.8 |

68% |

9.0*10⁴ |

2.4*10⁵ |

|

48 hours |

2001.9.7 |

07:50 |

28.1 |

68% |

8.7*10⁴ |

2.0*10⁵ |

|

72hours |

2001.9.8 |

08:30 |

28.9 |

69% |

1.2*10⁵ |

3.1*10⁵ |

|

9 days |

2001.9.14 |

08:30 |

29.4 |

65% |

1.8*10⁵ |

2.4*10⁵ |

|

14 days |

2001.9.19 |

07:40 |

28 |

77% |

1.1*10⁵ |

2.7*10⁵ |

Test 3 Wooden Floor+ PVC Carpet+ Conductive Floor Tiles

|

|

Test Date |

Test Time |

Temperature in °C |

Humidity Test |

Ground Testing |

Surface Test |

|

Adhesion Time |

2001.9.5 |

10:00 |

33 |

67% |

1.6*10⁵ |

3.3*10⁵ |

|

24 hours |

2001.9.6 |

07:50 |

28.8 |

68% |

7.7*10⁴ |

1.6*10⁵ |

|

48 hours |

2001.9.7 |

07:50 |

28.1 |

68% |

8.5*10⁴ |

2.1*10⁵ |

|

72hours |

2001.9.8 |

08:30 |

28.9 |

69% |

9.2*10⁴ |

1.8*10⁵ |

|

9 days |

2001.9.14 |

08:30 |

29.4 |

65% |

1.6*10⁵ |

3.2*10⁵ |

|

14 days |

2001.9.19 |

07:40 |

28 |

77% |

1.1*10⁵ |

2.4*10⁵ |

Test 4 Wooden Floor + Conductive Floor Tiles

|

|

Test Date |

Test Time |

Temperature in °C |

Humidity Test |

Ground Testing |

Surface Test |

|

Adhesion Time |

2001.9.5 |

10:00 |

33 |

67% |

1.3*10⁵ |

1.8*10⁵ |

|

24 hours |

2001.9.6 |

07:50 |

28.8 |

68% |

5.2*10⁴ |

2.1*10⁵ |

|

48 hours |

2001.9.7 |

07:50 |

28.1 |

68% |

4.9*10⁴ |

2.1*10⁵ |

|

72hours |

2001.9.8 |

08:30 |

28.9 |

69% |

6.8*10⁴ |

2.4*10⁵ |

|

9 days |

2001.9.14 |

08:30 |

29.4 |

65% |

2.0*10⁵ |

3.4*10⁵ |

|

14 days |

2001.9.19 |

07:40 |

28 |

77% |

8.0*10⁴ |

3.4*10⁵ |